ASTM A453 Grade 660 Class C specification provides a yield strength viz. 85 ksi [585 MPa] respectively for use in high temperature service for bolting components such as Stud bolts, screws, nuts, hex bolts & various other fasteners for pressure vessel and valve flanges. A453 Grade 660 Class C is oil quenched and double age hardened to achieve superior grain structure as compared to Class A,B & D . ASTM A453 Grade 660 Class C is produced in various other forms like wire rods, round bars, shafts, castings, forgings, threaded bars, threaded rods, wires, tubings, sheets, plates, welding rods, hex bars, Rivets & Springs. A453 Gr. 660 Cl. C Fasteners are stress rupture tested for 100 Hours at 650°C in finished condition. ASTM A453 Grade 660 Class C Bolting can be certified under nace provided the hardness is controlled and not over 35HRC.

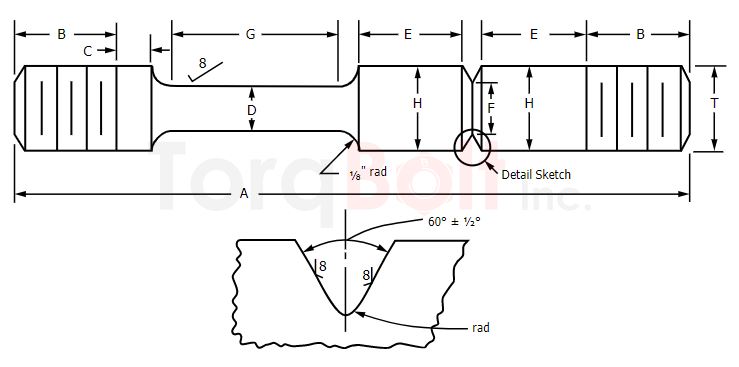

ASTM A453 Grade 660 Class C Product Range

A453 gr 660 class c

A453-660 class c

ASTM A453-660 class c

ASTM A453 grade 660 class c

ASTM A453 gr 660 cl c

ASTM A453 gr 660 c

ASTM A453 grade 660 c

A453 660c

A453 gr 660 c

A453 gr 660 bolts

A453 gr 660 class c

A453 gr 660c bolts

ASTM A453 660c

A453 grade 660 bolts

ASTM A453 gr.660 cl.c

ASTM A453 grade 660 class c

ASTM A453 grade 660 c

ASTM A453 grade 660 bolts

ASTM A453 grade 660 class c

SA 453 660 c

SA 453 gr 660 c

SA 453 gr 660 class c

SA 453 grade 660 class c

SA 453-660 c

SA 453-660 type c

Specifications

- ASTM A453

- ASTM A638

- EN 10269

- EN 10083-3

- ISO 3506-5

- DIN 267

Surface Treatments

- Xylan 1070 / 1014 / 1400 / 1424

- Xylar 2 / 101

- SermaGard 1105 / 1280

- Dacromet 320 / 500

- TakeCoat 1000 Ceramic

- Magnigard

- MolyKote

Certifications

- ISO 9001 - 2015 Certified

- PED 2014/68/EC

- NACE MR0175/ISO 15156-2

- NORSOK M-650

- DFAR

- MERKBLATT AD 2000 W2/W7/W10