ASTM A453 Grade 660 Class B specification provides a yield strength viz. 85 ksi [585 MPa] respectively for use in high temperature service for bolting components such as Stud bolts, screws, nuts, hex bolts & various other fasteners for pressure vessel and valve flanges. A453 Grade 660 Class B is equivalent to EN 10269 1.4980 and ASTM A638 Type 2 . A453 Grade 660 Cl B Studs and nuts are capable of meeting impact test requirements of 40 joules minimum at - 100 Degrees Centigrade. ASTM A453 Grade 660 Class B is produced in various other forms like wire rods, round bars, shafts, castings, forgings, threaded bars, threaded rods, wires, tubings, sheets, plates, welding rods, hex bars, Rivets & Springs. Class B Fasteners are stress rupture tested for 100 Hours at 650°C in finished condition. Class B Bolting can be certified under nace provided the hardness is controlled and not over 35HRC.

The operational limits of ASTM A453 GRADE 660B with 128 ksi actual yield strength (36 HRC) were determined by series of corrosion and environmentally-assisted cracking tests in various fluids. ASTM corrosion test coupons were subjected to 30-days immersion in aerated artificial seawater to evaluate pitting and crevice corrosion. Sets of triplicate C-rings per NACE standard TM0177 were machined for testing in both the H2S NACE limits of superduplex stainless steels and 11.6ppg CaCl2 brine. The tests revealed that A453 Grade 660 class B was severely restricted due to chloride stress-corrosion cracking though the alloy was found to survive 3psi H2S, 120,000ppm Cl- up to 300°F. The alloy repeatedly failed in the CaCl2 brine at a temperature as low as 200°F. Comparing these results with those of AF935, high-strength alloys for production environments appear to be well restricted to alloys with at least to 30 to 35 wt.% nickel and 2 to 3 wt.% molybdenum. Despite environmental limitations, ASTM A453 Grade 660 Class B may be considered for service equipment as well permanent equipment in some dry gas or deaerated water injectors. Seawater immersion tests indicate that A453 Grade 660 Class B outperforms 17-4PH, an alloy sometimes used in injectors.

Annealing & Ageing Cycles

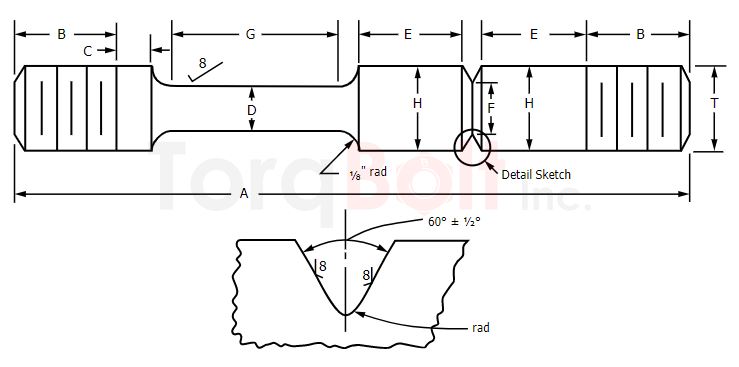

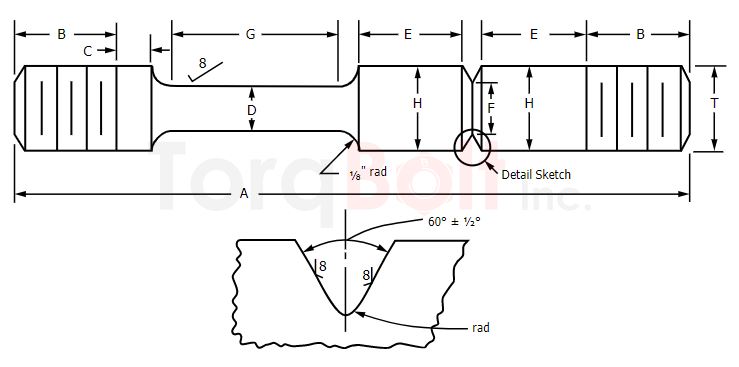

ASTM A453 Grade 660 Class B Product Range

A453 660b

A453 gr 660 b

A453 gr 660 bolts

A453 gr 660 class b

A453 gr 660a bolts

ASTM A453 660b

A453 grade 660 bolts

ASTM A453 gr.660 cl.b

ASTM A453 grade 660 class b

ASTM A453 grade 660 b

ASTM A453 grade 660 bolts

ASTM A453 grade 660 class b

SA 453 660 b

SA 453 gr 660 b

SA 453 gr 660 class b

SA 453 grade 660 class b

SA 453-660 b

SA 453-660 type b

Specifications

- ASTM A453

- ASTM A638

- EN 10269

- EN 10083-3

- ISO 3506-5

- DIN 267

Surface Treatments

- Xylan 1070 / 1014 / 1400 / 1424

- Xylar 2 / 101

- SermaGard 1105 / 1280

- Dacromet 320 / 500

- TakeCoat 1000 Ceramic

- Magnigard

- MolyKote

Certifications

- ISO 9001 - 2015 Certified

- PED 2014/68/EC

- NACE MR0175/ISO 15156-2

- NORSOK M-650

- DFAR

- MERKBLATT AD 2000 W2/W7/W10