ASTM A453 Grade 660 U Bolt

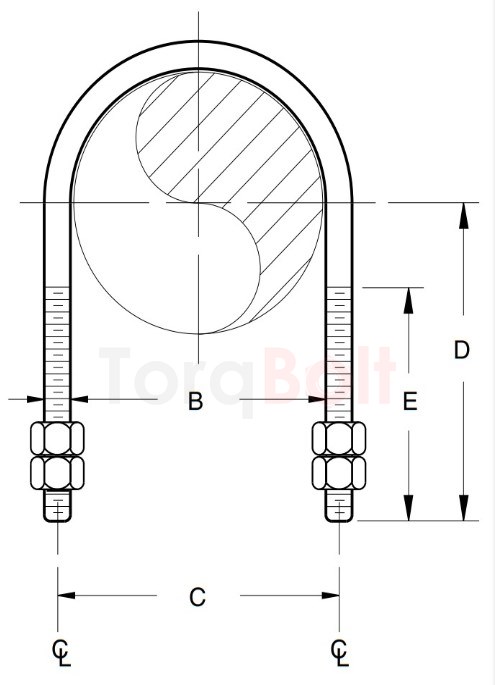

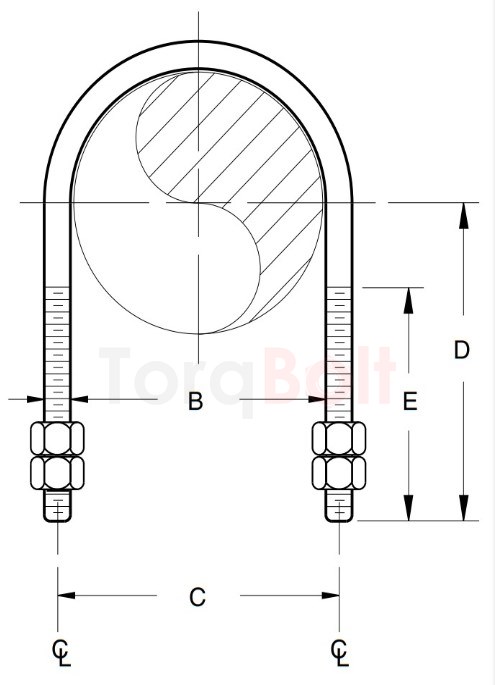

ASTM A453 Grade 660 Class A/B/C/D U-Bolts are recommended for use as supports or guides for piping for high temperature service. They are supplied with four hex nuts.

Compliance : Federal Specification A-A-1192A Type 24, MSS-SP 69 Type 24, and BSPSS-BS3974.

Side loads are given for the Figure 283 for a maximum temperature of 650ºF / 343ºC. When the loading condition requires the simultaneous application of a normal load and side load, the following interaction equation must be used to determine if the Figure 283 can be used.

(Actual Load / Maximum Design Load) + (Actual Side Load / Maximum Side Load) The result of this equation cannot exceed the value of 1.0 if the Figure 283 is to be used.

Ordering : Specify pipe size, figure number, and finish. For Metric applications Specify M283.

ASTM A453 Grade 660 U Bolt

Specifications

- ASTM A453

- ASTM A638

- EN 10269

- EN 10083-3

- ISO 3506-5

- DIN 267

Surface Treatments

- Xylan 1070 / 1014 / 1400 / 1424

- Xylar 2 / 101

- SermaGard 1105 / 1280

- Dacromet 320 / 500

- TakeCoat 1000 Ceramic

- Magnigard

- MolyKote

Certifications

- ISO 9001 - 2015 Certified

- PED 2014/68/EC

- NACE MR0175/ISO 15156-2

- NORSOK M-650

- DFAR

- MERKBLATT AD 2000 W2/W7/W10